Haina 6 Tuaka 1800mm Arm ka tae Aunoa MIG Welding Robotic Arm

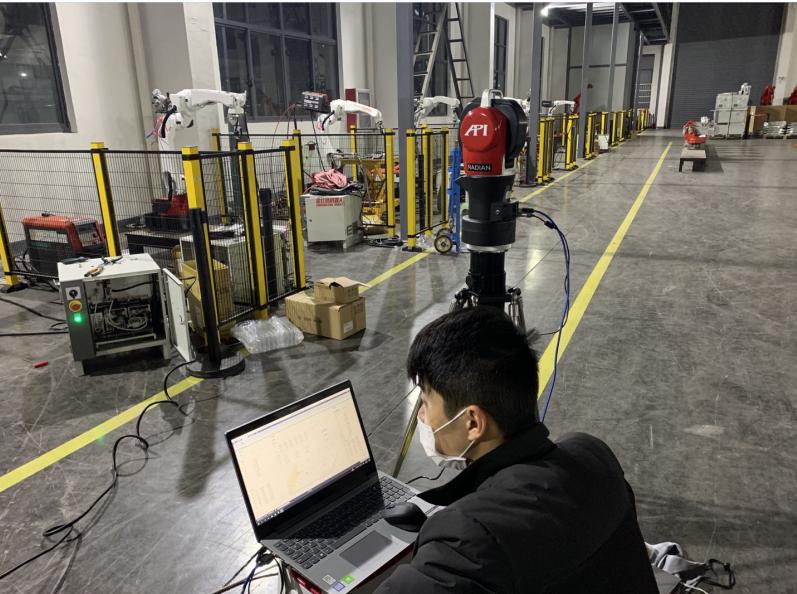

LASER CALIBRATION TEST REPOSITIONING ACCURACY

Ka whakamahia e JHY te tikanga whakatikatika taiaho hei whakamatautau i te tika o te tuunga o te karetao.Whai muri i nga whakamatautau maha, ko te tika o te tuunga o to tatou karetao he nui ake i te ± 0.08mm.

WHAKAMAHI I NGA MONO RUNGA MO NGA RANGATIRA MAHI

Ko nga taputapu matua karetao penei i te motuka servo, te whakaheke RV, te whakaheke harmonic, te taraiwa servo me era atu mea katoa e whakamahi ana i nga tohu o runga o Haina, kua whakamatauria e ta maatau whakamahi mo te wa roa kia pai ai to maatau robot.

WHAKAMAHI MAHI

He ngawari te tiaki, E ai ki te aratohu tiaki e whakaratohia ana e taatau ka taea e nga kaihoko te mahi ngawari.

I muri i te hoko taurangi

Kei ia kaihoko tana ake roopu ratonga muri-hoko.Mena ka hiahia koe ki te awhina i muri i te hoko, patai a Pls i nga wa katoa.Ka whakatauhia e a maatau miihini ngaio i roto i te waa poto rawa atu.Ko te take he kore utu katoa.

| Tohutoro tawhā fehokotaki'anga mo te maitai ngawari me te maitai koranu iti | |||||||||

| momo | pereti | Waea diameter | āputa pakiaka | naianei fehokotaki'anga | ngaohiko whakapiri | tere fehokotaki'anga | Whakapaa atu ki te pito-mahi tawhiti | Te rere hau | Koki fehokotaki |

| He reke te hanga-T | 1.0 | 0.8 | 2.5~3 | 70~80 | 17~18 | 8~10 | 10 | 10~15 | 45° |

| 1.2 | 1.0 | 3~3.5 | 85~90 | 18~19 | 8~10 | 10 | 10~15 | 45° | |

| 1.6 | 1.0,1.2 | 3~3.5 | 100~110 | 18~19.5 | 8~10 | 10 | 10~15 | 45° | |

| 2.0 | 1.0,1.2 | 3~3.5 | 115~125 | 19.5~20 | 8~10 | 10 | 10~15 | 45° | |

| 2.3 | 1.0,1.2 | 3~3.5 | 130~140 | 19.5~21 | 8~10 | 10 | 10~15 | 45° | |

| 3.2 | 1.0,1.2 | 3.5~4 | 150~170 | 21~22 | 7.5~8 | 15 | 15~20 | 45° | |

| 4.5 | 1.0,1.2 | 4.5~5 | 180~220 | 21~23 | 6.5~7.5 | 15 | 15~20 | 45° | |

| 1.2 | 5~5.5 | 200~250 | 24~26 | 6.5~8 | 10~15 | 10~20 | 45° | ||

| 6 | 1.2 | 5~5.5 | 230~260 | 25~27 | 6.5~7.5 | 20 | 15~20 | 45° | |

| 6 | 220~250 | 25~27 | 5.5~7.5 | 13~18 | 10~20 | 45° | |||

| 4~4.5 | 270~300 | 28~31 | 10~11.5 | 13~18 | 10~20 | 45° | |||

| 8,9 | 1.2,1.6 | 6~7 | 270~380 | 29~35 | 6.5~7.5 | 25 | 20~25 | 50° | |

| 8 | 1.2 | 5~6 | 270~300 | 28~31 | 9~10 | 13~18 | 10~20 | 45° | |

| 1.2 | 7~8 | 260~300 | 26~32 | 4~5.5 | 15~20 | 10~20 | 50° | ||

| 1.6 | 6.5~7 | 300~330 | 30~34 | 5~5.5 | 15~20 | 10~20 | 50° | ||

| 12 | 1.2,1.6 | 7~8 | 270~380 | 27~35 | 4.5~6.5 | 20~25 | 20~25 | 50° | |

| 1.2 | 7~8 | 260~300 | 26~32 | 4~5.5 | 15~20 | 10~20 | 50° | ||

| 1.6 | 6.5~7 | 300~330 | 30~34 | 5~6 | 15~20 | 10~20 | 50° | ||

Tuhipoka:

1. MIG fehokotaki'anga whakamahi hau inert, te nuinga whakamahia mo te fehokotaki'anga o te konumohe me ona alloys, parahi me ona koranu, Titanium me ona koranu, me te kowiri tira me te wera-ātete rino.Ko te whakarewanga MAG me te CO2 hau hei whakamarumaru i te maru ka whakamahia te nuinga mo te raima waro me te koranu iti te maitai kaha teitei.

2. Ko nga korero i runga ake nei mo te tohutoro anake, a he pai ake te whiwhi i nga tawhā o te tukanga whakawhanaunga tino pai ma te whakamanatanga whakamatautau.Ko nga diameter waea o runga kei runga i nga tauira pono.